If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Starlite has always been committed to provide more packaging options for our customers. Nowadays customers not only seek for high quality, but also pay increasing attention to the actual appearance of the product, APET is therefore the best choice that well combines the function of product display, product protection and serves as the package. From blister packaging, window box to APET box, Starlite's professional team with years of experience could always provide the most suitable packaging solution that will perfectly present your products and allow your products to stand out in the market.

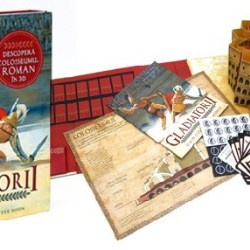

Starlite manufactures children’s books, novelty books and board games with the understanding that these products will broaden adult and child minds alike. With durability and presentation in mind, we specialize in expressing creativity on paper, resulting in pop up elements, unique shapes, fold-outs, and many unique features found in these products. We have printed a wide variety of different book sizes and specifications, such as oversized pop-up books, board games, puzzles, and book kits. At Starlite we believe that the sky’s the limit when it comes to your imagination and creativity.

As many children’s books and board games fascinate all of the human senses, we maintain a vast procurement network which allows us to obtain special materials required to add that special touch to your project. As children’s books and board games are often subject to strict safety standards, at Starlite we employ printing that meets these standards, such as using soy-based ink and complying with all safety/materials standards required.

If you’re ready to print your novelty book or children’s book, turn to the experts at Starlite, as we’ll bring your publication to life.

Starlite prints a wide range of roll and sheet form labels on different substrates, such as paper, plastic films, and more.

Using the Nilpeter MO-3300 Label Machine, this advanced platform-based press features multiple print options all in one run, including offset, flexo and gravure and silk-screen printing as well as in-line hot foil stamping, cold foil transfer, flat-bed/rotary die-cutting and film lamination processes. Additionally, this machine ensures the flexibility to handle all future printing and converting technologies to serve present and future packaging needs, maximizing business value and print efficiency.

In short, with the Nilpeter MO-3300 Label Machine, we can reconfigure press according to customers’ needs, therefore reducing tooling and prepress costs and expanding market opportunities for labels and flexible packaging.

With our extensive experience and state-of-the-art-technology, we can produce any label from simple to complex, bringing our business partners to the forefront in product presentation and customer satisfaction.

As a global leader in luxury packaging production, we are focused on providing superior print and box-making services for the premium branded goods market. We believe that unique, creative and high-end packaging is the key to attracting the consumer’s attention to these products in the marketplace, working in tandem with the product and brand to contribute to a display of quality and craftsmanship.

Starlite manufactures luxury packaging utilizing metallic foil paperboard and plastic film, along with a wide range of finishes including foil stamping, embossing, windows and film lamination for added shelf appeal.

Our goal is to ensure color consistency and high quality manufacturing for every order, making your product more recognizable and distinguishable to the consumer with visual and tactile presentation at a premium level.

Starlite manufactures a range of eco-friendly molded pulp products, perfect for a range of packaging needs. Molded pulp is a cost-effective and environmentally sustainable printing option that meets the demand for earth-conscious responsibility in packaging.

Constructed using recycled fibers that originate from paper products such as newspaper and cardboard, molded pulp is suitable for a vast array of products from drink or food trays, bowls and plates, to clamshell containers, egg cartons, shipping materials and point of purchase packaging.

Starlite is at the forefront of molded pulp innovation that goes beyond protective packaging and extends to beautiful surface applications. With die cutting, trimming, hot-stamping and other finishes, these effects have successfully been used to showcase products to consumers looking for environmentally-conscious branding.

Count on Starlite’s extensive molded pulp capabilities for excellent product protection and environmentally friendly packaging presentation that will exceed your expectations.

Starlite is a world leader in packaging production, as we can accommodate a broad array of different consumer and luxury packaging production projects. With integrated packaging production, we offer product development, prepress, press, die cutting and gluing, along with secondary processes all combined in an end-to-end workflow. Production is speedy, cost-efficient and dependable. This is the crucial difference.

We have decades of experience and expertise in a large variety of packaging, including packages for household appliances, toys and games, greeting cards, consumer electronics, food and beverages, luxury, pharmaceuticals, and personal care products.

Starlite also provides protective packaging solutions, such as molded pulp inserts, which are a sustainable and eco-friendly packaging option produced by our subsidiary, Greenworks International Limited.

For all of your food and beverage packaging needs, Starlite features a cleanroom as well as food-grade quality materials sourcing and printing that meet or exceed industry requirements for food packaging such as chocolates, beverages, or snacks.

Whatever your packaging needs, Starlite is passionate about using printing and packaging to elevate your brand and marketing.