If this is your company, CONTACT US to activate Packbase™ software to build your portal.

How can intelligent packaging create a unique customer experience hence increase brand loyalty? This will be presented by Stora Enso through tangible business cases in a round table discussion as part of the Luxe Pack Monaco conference programme 22 October 2015.

“Luxury brands can leverage the high potential of intelligent packaging functionalities in many different ways. In cooperation with our partners we offer an extensive range of intelligent features in packaging, which can be used for consumer engagement and brand enhancement. It can also be used for proof of product authenticity and origin, tamper evidence and even further to source and delivery tracking and supply chain optimization. As the world is moving increasingly into internet-of-things age, there is a great business potential to be captured with these value adding features,” says Timo Sokka, Head of New Business Development at Stora Enso Consumer Board.

Stora Enso cooperates with NXP, one of the market leaders in RFID (Radio Frequency Identification) and especially in NFC (Near Field Communication), to provide solutions to market and brand driven needs with state-of-art collaboration and networks. The intelligent features give brand owners an in depth understanding of what is happening with consumers and their products, by providing data about product transactions and consumer activity, increasingly in real-time.

“We are looking into premium product appearance and intelligent functionalities with various different technologies: RFID and NFC, indicators and sensors, light, sound and even display effects. Our interest is to engage brand owners into discussions on needed solutions and to create a tangible path together to fulfill their needs. Our target is to offer brand enhancing packaging for the future with renewable materials, value added functionalities and creative design,” says Sokka.

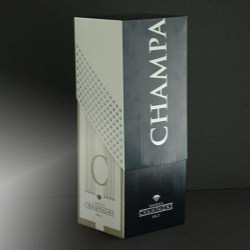

The practical examples shown at Luxe Pack range from a champagne package that works as an ice bucket with illumination effects to a fragrance package with illumination, tamper evidence and an NFC app for brand authentication and consumer engagement.