If this is your company, CONTACT US to activate Packbase™ software to build your portal.

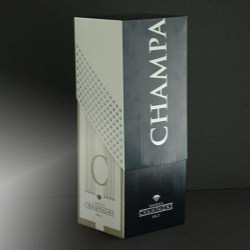

Stora Enso introduces DuraSense™ by Stora Enso – wood-based biocomposites for premium cosmetics, food and luxury brands seeking alternatives to plastic packaging. With the help of DuraSense, customers who place very high demands on aesthetics and tactile values can make their packaging more eco-friendly.

Introducing DuraSense to new customer segments is another step on Stora Enso’s journey to gradually replace fossil-based packaging materials with renewable solutions. DuraSense is a blend of wood fibres and polymers, which can be fossil, bio-based or recycled. With DuraSense, Stora Enso offers customers a more eco-friendly alternative to plastics while improving sustainability performance and reducing carbon footprint. With the blend of wood fibres and bio-based polymers, it is possible to get up to 98% renewable content and, thus, reduce the dependency on limited fossil resources.

“Reducing the amount of plastic is high on our customers’ agenda, and they want help in replacing non-renewable materials. With DuraSense we can now offer different biocomposite solutions, such as caps and bottle stoppers, to demanding customers in premium cosmetics, food and luxury segments with very high standards in both aesthetics and quality,” says Hannu Kasurinen, SVP Head of Liquid Packaging and Carton Board at Stora Enso.

DuraSense is a cost- and resource-efficient alternative for reducing the environmental impact of products. With little or no change to existing production techniques, the biocomposite material is developed to match conventional plastics and therefore fit existing moulds.

“With wood-based biocomposites, the consumption of plastic materials can be reduced by up to 50%, ensuring that less plastic ends up in the environment. DuraSense can also be reused as a material up to seven times, recycled along with plastic materials or used for energy recovery at the end of its life,” says Lars Axrup, Head of Business, Sustainable Packaging Components at Stora Enso.

Stora Enso started the commercial production of biocomposites in 2018 and has the largest capacity in Europe dedicated to wood-fibre-based composites. The raw material for DuraSense comes from sustainably managed Nordic forests covered by third-party-certified Chain of Custody systems.