If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Tetra Pak has launched new best-practice lines for yoghurt products - a suite of expert services which support a wide variety of yoghurt innovations to address growing consumer demand. Leveraging more than 45 years of experience in processing and packaging solutions with deep knowledge of yoghurt, enabling Tetra Pak to offer support for designing processes that do not compromise on production economy or flexibility.

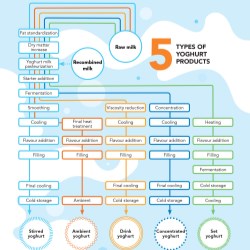

The best-practice lines support the design of customised solutions for five types of yoghurt products: stirred, set, drinking, concentrated and ambient. These are specific sets of guidance which can be tailored to match particular production needs of different types of yoghurt.

“Rapidly shifting consumer preferences and a sustained focus on health means that our customers need to be simultaneously agile, specific and consistent in their production,” said Frederik Wellendorph, Vice President Liquid Food at Tetra Pak. “Using expertise gathered from more than 300 yoghurt equipment installations worldwide, we can partner with customers to help them reach a new level of ‘yoghurt-fluency’ and better enable business growth.”

Bruno Girão, CEO of a Brazilian company Betânia, said “By converting chilled yoghurt into ambient, we can now sell our products in northeastern Brazil without having to invest in a costly chilled distribution chain. It’s an innovative approach that is helping us expand our business,”

Tetra Pak has been working with Betânia on a customised processing solution at a dedicated Product Development Centre (PDC) in Monte More near Sao Paulo.

.png)

.jpg)