We are drowning in plastic. As terrifying as it sounds, it is an unavoidable truth. Since 1950, approximately 9.2 billion tonnes of plastic have been produced globally; yet, only about 30% are still in use. The lack of information on the general population and poor recyclable options in most markets have reduced the amount of recycled plastic waste to a sad 9%. This means 19% is incinerated, polluting our air; 50% is sent to sanitary landfills, polluting our land; and 22% is dumped directly into the ocean, polluting our water.

If current policies are not changed, global plastic waste generation is expected to triple by 2060. However, if companies significantly improve their recycling systems, this number could be reduced to less than 700 million tonnes. The global manufacturer and supplier of pumps and roll-on bottles, TKPC, knew it had to jump into action and be an active part of the environmental revolution.

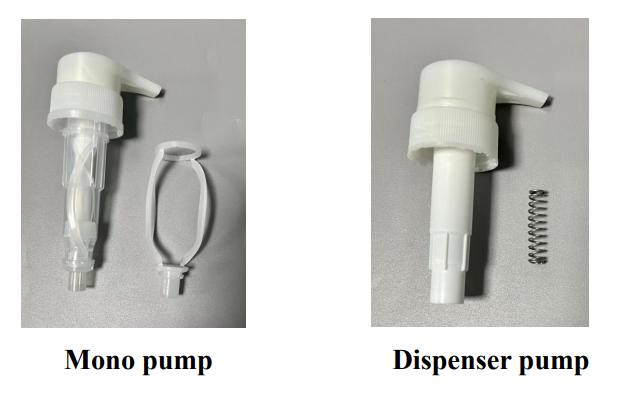

In 2007, we applied for the first patent, which was called "Lotion Pump and Its One-Way Valve," a sustainable pump that could be made of a single material—PP or PE. The pump's head design removed the spring to ensure the dispenser would be properly disposed of in recycling facilities. In the past fifteen to sixteen years, we have always insisted on developing environmentally friendly, high-performance, and easy-to-recycle pump heads.

Mr. Ding Yaowu, Chairman of TKPC, speech in an exclusive interview with "New Observation on Waste Plastics" in January 2022

TKPC's Mono Pump Series

Inspired by hunters, the TKPC R&D team developed a unique elastic reset mechanism made entirely of plastic, designed on the same underlying principle as a bow. Normal dispenser pumps contain metal springs, glass beads, or stainless steel beads and plastic parts made of various materials. The variety of materials and low recovery value make them difficult to recycle. The development of the Mono Pump, made of 100% PP, on the other hand, meant this dispenser did not need to be disassembled in any way, being easy to classify in recycling facilities and, thus, easy to recycle.

Additionally, the development of TKPC's new line of pumps introduced new features that would enhance the overall product, including:

- The introduction of a special clutch design that protects the spring from pressure when not in use, ensuring that the pump head can be preserved for more than three years in the unopened state.

- The bow-shaped spring design creates more energy when pressed, meaning it has a stronger rebound, and viscous liquids can be dispensed with less effort.

- The lack of metal components increases acid resistance, making the mono pumps especially suitable for high-acidity liquids like fluoride toothpaste.

- The automotive clutch operating principle: closed when in use, disengaged when not in use, this unique plastic spring has a lock-down function that prevents leakage, making it suitable for e-commerce transport.

Want to learn more? Contact us now and get your project started. The sooner we act, the better it will be for everyone.

.png)

.png)