Public

About S Pack

Professional Procurement Network

S Pack Catalog

S Pack Locations

S Pack News & Packaging Updates

S Pack Packaging Gallery

S Pack's Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

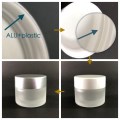

Decoration for opal glass packaging:

- High temperature printing: Printed with heated ink and then baked under 600°C treatment, the benefit of having opal glass components decorated with high tempreture printing is to have endured and solid decorative images.

- High temperature treatment with foil: Printed with decorative foil sheet, and then baked under 600°C treatment, the result is a solid decoration with vivid visual impression.

- Low temperature trreatment with foil: Optimizing foil decoration with low tempreture is the best decoration possible for opal glass. The presented image is clear with strong contrast.

- Low temperature treatment with spray coating: The spray coating on pure white opal glass creates a gentle solidness that is similar to jade.

- Nano-plating: The decoration adds a further endured coating with sheer prettiness.

- Water transfer printing: It is possible to decorate opal glass component entirely regardless of its unique shape. The decoration wraps up objects to cover every curve.

- 3D printing: 3D printing enables an instant and immediate decoration to visualize artwork. It is an easy access to present best customization possible thanks to modern technology.

Opal glass

Opal glass is a kind of glass porcelain. White, the symbol of purity, is the most mysterious color. Opal glass, originating from Venice, Italy in the 16th century, is a kind of glass material in an opaque or translucent, milky white or tinged color, which can be blown or compacted into all manner of shapes. It was once called milky white opaque glass by glass makers and is now called opal glass.

In general, glass is a non-crystalline substance and a kind of super-cooled liquid. Therefore, if glass is kept at an appropriate temperature for a long time, it will precipitate crystallization, which is known as devitrification. Usually, the crystals resulting from glass devitrification will have large coarse grains (5-50um). Also, like opacified glass, the crystallization will have a very small volume. By utilizing this phenomenon of devitrification, people artificially control types and growth of crystallization, making part or all of the glass become an aggregate of micro crystallines (less than 1ym) — which then becomes opal glass.