If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Totempak

innovating the safest cup for the world

In Totempak, We Safeguard the Safety of Disposable Paper Containers for the Consumers

Totempak is founded in 2011, its founder, Mr. Morgan Lin is a 20-year veteran in the paper-importing business, and has a wealth of understanding in the characteristics and applications of various paper materials. He has also been in a long-term commitment to improve the safety of paper containers, and through the years of R&D, he made many technological breakthroughs, obtaining over 160 international patents. All his efforts are toward one goal: to produce the safest, most hygienic, and environment-friendly paper container for the consumers.

Therefore, every step from cup stock paperboards to production is implemented with high standards. Situated in Nangang Industrial Area of Nantou, the entire 20,000m² factory is certified by ISO22000&HACCP food-grade standards, as well as receiving relevant certifications from TUV Rheinland (100-121℃ heat-resistant), LFGB, and SGS Microwaveable Testing etc..

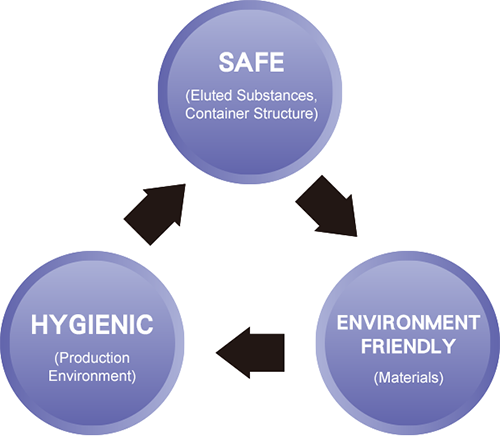

The 3 Requirements in Paper Cup Production

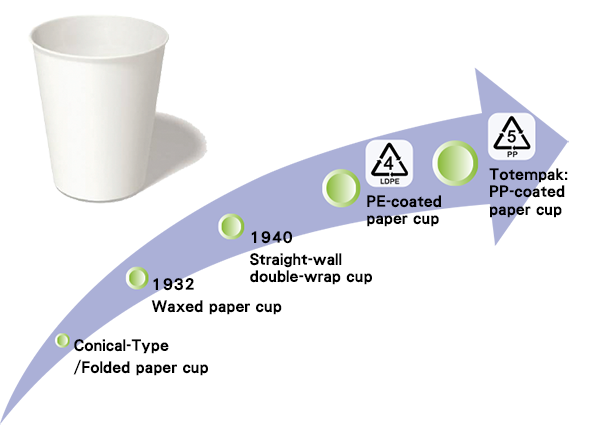

We Revolutionized Paper Cup Manufacture

We Adopt Food-Grade Safety Standards in Making Paper Containers

Under our principle for “the safest paper containers,” we subjected our entire plant to ISO22000 & HACCP criterions, food manufacturing standards, to ensure our production environment complies with the food safety standards. Additionally, we also sent our products to relevant units both foreign and domestic for inspections in order to ensure our products comply with all quality standards.

Obtained ISO22000 and HACCP Certifications from SGS

The ISO22000 system certification aims to ensure the food safety and reliability in the food supply chain, while the HACCP is currently the best of food safety management system acknowledged internationally. The aim of HACCP is to confirm and eliminate every possible hazardous physical, chemical, and biological risk to the consumers as soon as possible. Its prerequisites are to introduce safety concepts and maintain effective food inspection methods in the plant facilities and technology.

Passed the TUV Rheinland 121℃ Heat-Resistant Certification

The German TUV Rheinland was founded in 1872, and is now one of the largest product and quality certification agencies in the world. It provides approximately 2500 kinds of services, focusing in 39 fields, involving 6 major service scopes: industrial, transportation, product, life science, educational, and consulting, and management system services.

Passed the test specification of German LFGB paragraph 30, 31

The LFGB is the commonly accepted food container safety regulations and standards commonly recognized by the EU. Except currently in Taiwan, regulated heavy metals, fluorescent agents, elutedsubstances migration, there are also approximately 30 inspections involving microbe and pesticide residues. The certification can only be acquired by passing all of the inspections, as well as obtaining the right to engage in sales in the markets of the EU member states. Additionally, the EU also requires products to be labeled with the cup & fork mark for the consumers in order to show that the products have passed relevant inspections and regulations.

Passed SGS Microwave oven test, maximum resistance: 1200W/390 sec

SGS is a certification body which certifies management systems such as plant certification and product certification, as well as chemical testing. SGS was founded in 1878 with headquarters in Geneva, Switzerland, and its global service network is comprised of over 1000 branches, 360 laboratories, and 40000 staff in over 160 countries around the world.

.png)

.png)