If this is your company, CONTACT US to activate Packbase™ software to build your portal.

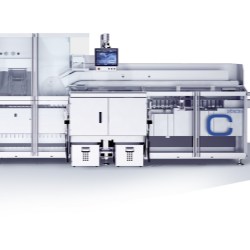

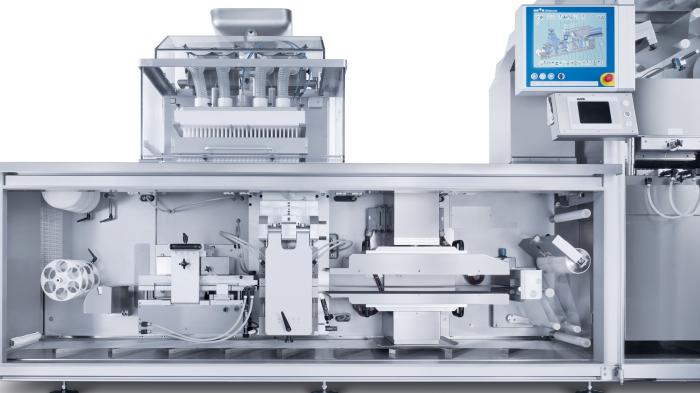

For solid dose products in large batches

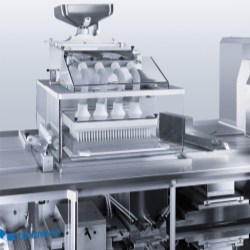

The high-performance blister machine with innovative technology for optimum process reliability packages all forms of solid dose products such as tablets, capsules, or coated tablets in all common types of forming material.

Highlights

- Depending on the application, intermittent motion platen or rotary sealing

- Servo-regulated drive for accurate embossing and perforating

- Integrated, gentle blister removal and transfer to cartoner with minimum number of format parts

- Pharmaceutically compliant separation of drive and operating zones

- Very good accessibility as glass safety doors with innovative sliding and closing mechanism

| Blister machine B 1660 | |

| Max. output | 750 blisters/min. |

| Sealing principle | platen and rotary sealing |

| Mode of operation | 3-lane |

| Scope of application | solid dose products |

| Max. format area [index x width] | 280 x 284 mm, 280 x 320 mm* |

| Max. forming depth | 12 mm |

| Max. reel diameter | forming material 1,000 mm, lid material 400 mm |

| Processable forming materials | Al laminates, PVC, PVC/PVDC, PVC/Aclar, PET, PP**, COC** |

| Processable lid materials | Al, paper/Al, polyester/Al, PP** |

| *optional format upgrade | |

| **only with continuous motion rotary sealing |