If this is your company, CONTACT US to activate Packbase™ software to build your portal.

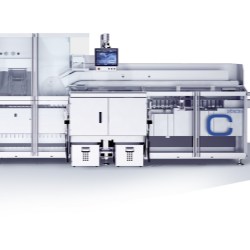

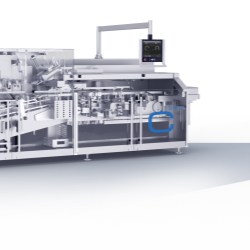

The added-value machine in the compact range

Attractive price, excellent production performance, and customary top Uhlmann quality: these are the attributes of a single-lane unit that perfectly integrates a blister and a cartoner module in a line measuring 8.4 meters. The BEC 300 is the ideal line for the processing of all common solid dose products and types of forming material in batches of 10,000 to 70,000 packs.

Highlights

- Great diversity in the processing of all common types of forming material, product shapes, carton sizes, and types of carton closure

- Smooth surfaces for fast line clearance

- Latest control and drive generation

- Tool-free format changeover in 30 minutes as few, lightweight format parts

- Intuitive SmartControl operating system

- Smart Xchange with USB flash drive enables the fully automated input of new format parts and the transfer of process parameters to other lines

| Blister line BEC 300 | |

| Blister module | |

| Max. output | 300 blisters/min. |

| Mode of operation | single lane |

| Scope of application | solid dose products |

| Sealing principle | rotary sealing |

| Max. format area [index x width] | 200 x 145 mm |

| Max. forming depth | 12 mm |

| Max. reel diameter | forming material 600 mm, lid material 300 mm |

| Processable forming materials | laminated Al foils, PVC, PVC/PVDC, PVC/Aclar, PP |

| Processable lid materials | hard Al, soft Al, paper/Al, Al with defined hardness, others on request |

| Cartoner module | |

| Max. output | 150 or 300 cartons/min. |

| Scope of application | blisters |

| Max. carton size [A x B x H] | 115 x 100 x 150 mm (150 cartons/min.), 105 x 105 x 155 mm (300 cartons/min.) |

| Pitch | 140 mm |

| Max. no. of blisters | 14 |

| Max. blister stack height | 95 mm |

| Types of closure | tuck-in and hot-melt |