If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Straightforward functionality for versatile use

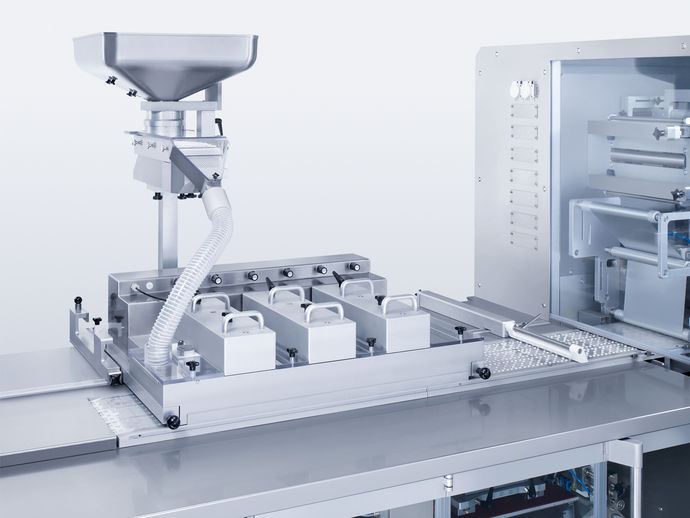

The brush box feeder is particularly suitable for all products that can easily be swept into the pockets, e.g. bi-convex products and capsules. As format parts are not dictated by the product shape, this feeder is the cost-efficient option for a wide range of applications on all blister machines.

Highlights

- Cost-efficient on account of random feeding with sweeping technology

- Versatile feeder for many product shapes

- For all thermoforming materials

- Low-cost format parts

- Fast changeover and cleaning of format parts

Operating method

- The products pass from the hopper to the vibratory chute. Dedusting here removes dust and product chips

- The products move through the product chute and feed hose into the brush box feeder box

- Rotating brushes and planetary stirrers sweep the products into the formed pockets

- To optimize filling efficiency the speed of the brushes and stirrers as well as their height setting from the web can be adjusted individually