If this is your company, CONTACT US to activate Packbase™ software to build your portal.

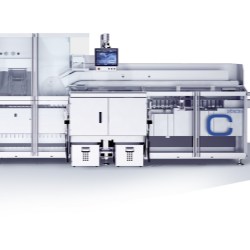

Highlights

- Widely applicable feeder for diverse product shapes

- Tool-free format changeover – quick and easy

- Compact design

- Separate control and operating panel allows configuration with every suitable blister machine, including equipment from other manufacturers

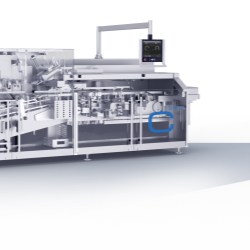

Operating method

- The products pass from the hopper to the vibratory chute. Dedusting here removes dust and product chips

- The products continue through the product chute and feed hose to the distribution box

- The up-and-down-movement of the sorting plate moves the products into the filling tubes. The two stop fingers in each filling tube ensure direct product placement into the formed pockets

- The lower stop finger retains the product and first releases it when the web comes to a halt

- The upper stop finger ensures that only one product reaches the pocket by retaining the product column above