UKPACK packaging offers many different PP and rPP Jars that are available in a number of attractive finishes and styles.

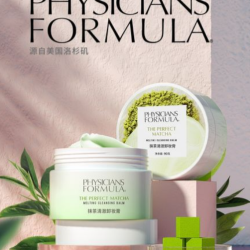

The capacity of the PP jars ranges from 5ml to 500ml making them suitable for a number of skincare and body care products. PP jars are often used as a product for body milk, facial mask, hair mask and cleansing cream packaging, to name a few.

At UKPACK's facilities, the jar's outer layer and inner layer can be injected in different colors. There is also a choice for the shape of jars: rounded with straight edge cap, rounded with a rounded edge cap, urn style and curved. UKPACK can color match to fit your brand with in-house printing and decoration. Be assured that the company's Quality Control team will check the quality of all products before the shipping process. PP Jars can also be produced to incorporate PCR.

PP jars supplier

UKPACK has a wide range of standard PP jars available, such as the softline, the straight and the stackable versions. Neck size 89-400 jar and 70-400 jars are available in a range of different sizes: 5ml,10ml ,15 ml, 30 ml, 50 ml,80ml 100 ml,150ml, 200ml up to 500 ml in standard PP. If this range doesn't fit your requirement, customized services are offered.

PP cream Jars – more information:

The most common plastic used in the construction of jars is polypropylene or PP. This abbreviation is the general name for a number of different varieties of PP like homopolymer, copolymer and random copolymer used in the injection moulding of PP jars. PP as a material is often used for making cream jars and containers as it has good product resistance to fats and almost all other organic solvents.

Injection moulding of the PP jars

The injection moulding (IM) process is known for its flexibility in materials and the preciseness of the PP parts. Pellets of PP material are fed into the hopper of the machine and then heated up the thermoplastic PP material to the right temperature for processing. This heating process is created by a combination of the heat from a barrel and the shear created by the screw.. When enough material has been processed, the injection machine forces the heated material under pressure into the injection mould to form the components of the PP jar. The injection moulds for PP jars can be made with 2 cavities up to 16 depending on the size and the design of the jar. As the PP jar should be able to be released from the injection mould there is always a draft angle and the jar, therefore, is always slightly conical.

One of the main advantages

One of the main advantages of the injection moulding of jars is that the surfaces can frosted; an effect which is created by treating the outer plate of the injection mould. When the injection mould is filled during the moulding process, the surface of the mould creates the frosted or matt effect on the PP jars.

Two types of PP cream jars

Basically there are two types of PP cream jars: the single waled and the double-walled. The construction of the double-walled PP jars consists of an inner jar which is fitted into an outer jar. The inner jar is injection moulded, completed with the neck finish and then mounted into the outer jar on an assembly line.

The inner jar is mainly produced in PP material as this plastic has very good product compatibility properties and when assembled gives the jars a more luxurious appearance. A single-walled PP jar consists of one part and is, therefore, more cost-effective.

Multiple or single-thread cream PP jars

Standard contents for the double wall jars are 5 ml, 15 ml, 30 ml, 50 ml and 100 ml but larger content sizes like 150 ml 200 ml 250 ml 300ml and 500ml are also available.There are different neck sizes and thread designs available for the cream jars. The most common one is the multiple start but a continuous thread version is also available.

Screen printing, Labeling and other decorations for PP jars

The body of the PP jar is slightly conical but a label can usually be easily applied. In specific cases jars can be screen printed in up to 6 colours.

Although the costs of screen printing is usually higher than labelling, the filling of the PP jars is easier and faster.

To decorate the cosmetic jars a hot stamp is often applied by using metallic foils. These foils can have numerous effects like a glossy or matt finish in combination with metallic silver and gold colours.

Stackable caps for the PP jars

There are numerous lids and closures available for the PP jars.

For certain products the requirement is that the jars are stackable so the cap needs to be designed in such a way that the bottom part of the PP jar actually fits the lid. The PP lids can be more rounded or feature a flat and straight design.