If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Yonyu Plastics provides complete solution from packaging design, molding & tooling, packaging production, formulation design, and filling. Its complete contract manufacturing solution benefits companies seeking for satisfying services.

- According to customer’s 3D design, and with the practice of reverse engineering and the aid of Pro-E software to convert to CAD/CAM, and CNC program, we are able to transform the customer’s design concept into reality.

- To engage CAE mold flow analysis software in mold design, to avoid tooling mistakes and to shorten mold development lead time.

- With a strong RD team, integrating raw materials and design data, a control chart was set up in the early stage of development process to keep the customer’s launch schedule on time.

- Multilayer co-extrusion blow molding process: a combination of different materials and colors, developing multilayer co-extrusion bottles to enhance additional values

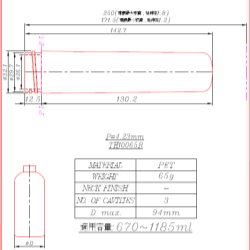

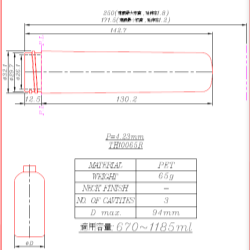

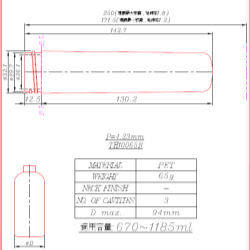

- PET / PP bottles Injection Blow Molding Process: Various Injection blow molds are available on demand, and with the modified PET / PP material; high-end packages, such as imitate glass / soft touch bottles are developed.

- Automated Injection Process: By using automated high speed injection systems from Europe and Japan, which are linked together with automatic detection system to reduce the risk of production defects.

- Automatic tube line: Integrating tube extruding / head injection / printing / capping machines, and online testing system, all composed into a one-pass process production line, effectively increase production speed and quality stability.