If this is your company, CONTACT US to activate Packbase™ software to build your portal.

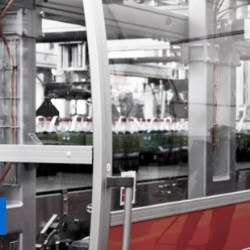

ACMI charts a new way forward in the design and construction of complete bottling systems. ACMI's Compact Line is growing in popularity especially among bottlers of soft drinks and mineral water. It is a system that eliminates all the accumulation tables, except for the one that combines the filling block with the packaging one and considers the bottling line as if it were made up of two large homogeneous blocks for performance and efficiency.

The Compact Line is a concept that leads us to consider the entire line as a single machine, a single system. In this system the various components work and move in a synchronous manner generating a continuous flow which originates from the filler and ends with the finished pallet. The traditional accumulating tables that have the task of harmonizing the different efficiencies of the single machines disappear, offering the following advantages:

- Reduction in space

- Reduction in purchasing costs

- Reduction in running and maintenance costs

- Elimination of the stress on the bottle due to squashing and pressure of the accumulating table

- Low total cost of ownership (tco)

- Great operating autonomy

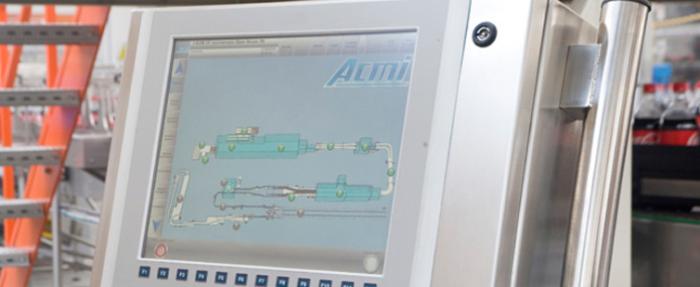

The Compact Line is managed by a single control panel that checks the various components of the line and adapts them to the fluctuations of the individual machines. The automatic changeovers of the consumable materials allow greater operating autonomy and a very high level of overall efficiency.