If this is your company, CONTACT US to activate Packbase™ software to build your portal.

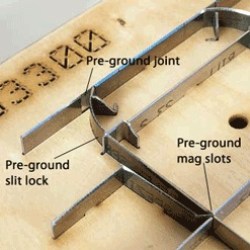

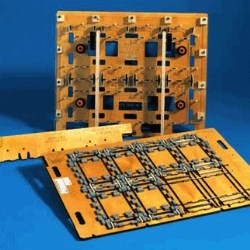

Specially produced for the Marbach Group, the mpower rule has a slight radius (0.02) on the cutting edge. Conventional knives need bedding in before consistency of cut is achieved, this takes approximately 1,000 impressions. The radius cutting edge on mpower rule needs no such process due to its design. The rule is capable of absorbing up to 3 times the pressure of conventional rule before damage occurs. Therefore more machine tonnage can be applied to the die to reduce the amount of manual patch-up.

Added Benefits:

- Higher production through consistency levels

- Reduction of board dust / swarf

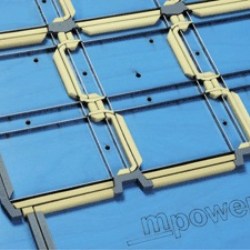

M345 Plates

The advanced M345 plate has a Rockwell hardness three times greater than standard 1 mm plates. It provides a high quality alternative thin plate and is beneficial when M-Power dies are used. With M345 plate, the convertor can have a thin plate with similar characteristics to a thick plate. Where as standard thin platescan groove easily, which may lead to swarfing on carton blanks resulting in extra cleaning before despatch.

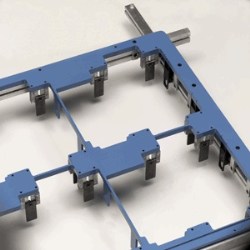

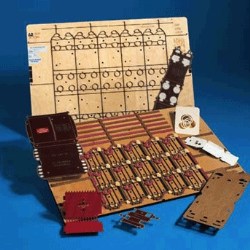

Mpower Rule - A Complete Solution

Arden Dies guarantees that each of its approaches to reducing patch-up times will give measurable benefits to productivity. A full technical support package is offered, with specialist advice and on site training to ensure your company has the latest die tooling technology.