If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Constantia Flexibles proves that recyclable packaging solutions can also show excellent barrier properties with the product innovations PERPETUA and PERPETUA ALTA. Therefore, pharmaceutical products can be packaged not only safely but also sustainably. Constantia Flexibles will present its product innovations and established packaging solutions in the pharma sector at the world's largest packaging trade fair, PACK EXPO International, in Chicago from 23 to 26 October 2022.

Product safety is the top priority of every pharma packaging solution. Sustainability often plays a secondary role in this process. However, the demand for environmentally-friendly packaging is growing. Consumers and entrepreneurs increasingly focus on products with the smallest possible environmental footprint. "In our Research & Development department we place equal importance on the safety and sustainability of our packaging. Our packaging is only fit for the future if it meets both our standards. With the PERPETUA and PERPETUA ALTA innovations, we combine both – performance and sustainability," says Pim Vervaat, CEO of Constantia Flexibles.

"In our Research & Development department we place equal importance on the safety and sustainability of our packaging. Our packaging is only fit for the future if it meets both our standards." Pim Vervaat, CEO.

PERPETUA: sustainable packaging solution with high barrier properties

PERPETUA is made of recyclable polypropylene-based mono-material. Its excellent barrier properties make it ideal for pharmaceuticals. PERPETUA protects products in the best possible way from oxygen, water vapor, and light. This is essential to maintain the efficacy of medicines. In addition, the product line is cyclos-HTP certified, which means that its recyclability is between 90 and 96%, depending on the individual material specification.

PERPETUA ALTA: Recyclable solution with high chemical resistance

The further development of PERPETUA ALTA is based on polypropylene (PP), is recyclable, and has a high chemical resistance to pharmaceutical products. It can therefore be used for excessively demanding products from both the pharmaceutical and food industries. The unique characteristic of the mono-material solution is the combination of sustainability and resistance. In addition, compared to conventional laminates, it is lighter, has higher efficiency, and offers optimal protection against oxygen, water vapor, and light.

Child safety and anti-counterfeiting features for even more security

High-performance packaging protects medicines so that their efficacy is maintained. But safeguarding against counterfeiting and unwanted consumption by children are also factors that must never be neglected when developing pharmaceutical packaging. To prevent children from getting hold of the contents of medicines, all Constantia Flexibles product lines are available in various child-resistant designs. These can be individually designed. Constantia Flexibles also invests in the further development of counterfeit-proof components of packaging because around 10 to 30% of the world's medicines are counterfeit. The original medication’s high level of security can only be guaranteed if the outer packaging is equipped with identification features, and the primary packaging shows counterfeit-proof features. Many of Constantia Flexibles' product lines are therefore available with anti-counterfeiting features.

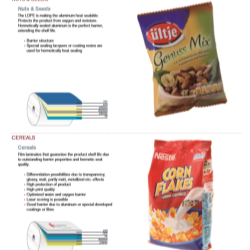

In addition to the innovations, Constantia Flexibles will be presenting its established product lines at the PACK EXPO trade fair. Further high-performance packaging for different applications, such as oral, injectable, or pulmonary administration, can be found at the Constantia Flexibles stand at PACK EXPO 2022.