Public

Fancy & Trend Catalog

Fancy & Trend Certifications

Fancy & Trend Gallery

Fancy & Trend Locations

Fancy & Trend News

Fancy & Trend Updates

Fancy & Trend's 3D Studio

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Recently, we conducted an interview with Aaron Lin, the current Sales Manager at Fancy & Trend. We learned all about the company's shift in focus from being strictly an OEM firm to moving into the ODM space and everything involved in that process. It's an exciting time for Fancy & Trend!

In what is Fancy & Trend mostly involved?

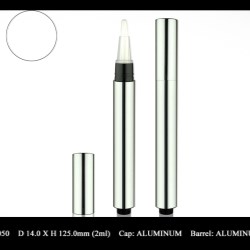

Our main product focus is cosmetic and skin care packaging, but we also provide one-stop service for customers including complete logistic services. We have the most competitive prices and the best services in our area, offering a wide range of products that can fulfil a client's most creative and demanding ideas for 21st century packaging. We're really proud of our ability to offer speedy turnaround on all sorts of projects, as well as the high quality of the items we produce.

How is Fancy & Trend different from competitors?

We are a totally ISO-certified supplier, endeavoring to provide high quality products and services. Our mission is to introduce evocative, high-quality, contemporary packaging to our customers. Over the past few years, we've gone from being a simple OEM provider to offering full ODM services for co been able to incorporate 3D printing technology and services into our processes to reduce the cost of development for customers and offer rapid prototyping. Thatisn't something we need to do on our OEM lines, but for ODM projects, it means we're highly competitieve with regard to time to market and cost

What's your role in that process?

I am the supervisor of the overseas sales department, also in charge of serving foreign customers to fulfil their needs. We have two locations, in Taiwan and in China but our main target markets are in America and Europe. Since the cosmetic market is so broad we are always looking for ways to enter other markets, so that we can add them to our target list and attack them efficiently. Tat's part of my mandate, to keep existing markets supplied and to spot opportunities in places where we may not have a large presence thus far.

Was the switch to offering bespoke manufacturing difficult?

Not really, it just meant that we had to make sure we kept our processes aligned and steady. One of the benefits of being ISO certified is that you really develop a feel for company processes. By adjusting our way of working slightly, we were able to fit ODM manufacturing into our operations smoothly. We've launched many items that way and we keep getting better and more responsive at it. It's something that took a little bit of realignment to achieve, but now that we've gottenthe hang of it, things are going really well.

What sort of customers have used your ODM or OEM services?

We've done projects for a number of unternational brands and large filling facilities all around the world. Nevertheless, we still work with a lot of small firms and start-ups just launching their brands. They tend to have limited resources and opt for standard items from our catalogue, then avail themselves of our decoration facilities to make their packaging unique. With regard to large brands, we've done work for Boots' No. 7, Inglot, Tarte, Bottega Verde, Lise Watier, and ROHTO. We've done work with a lot of small- and medium-sized brands from all over the world.

What are your next steps and what challenges does Fancy & Trend face?

We are trying to become familiar with Japanese business culture and the unique demands of that market. We are preparing a large push to enter this market imminently. Before we do, however, we need to be sure that we understand their specific needs, how they prefer to communicate, the sort of designs they like, etc. When you're talking about new markets, you can't leap before you look, you need to do your homework and plan ahead, you need to acquaint yourself with as mch as you can. In terms of challenges, I'd say our biggest one right now is figuring out how to compete with suppliers that offer lower quality and prices. We need to make pur customers and prosepective customers aware of the fact that we produce excellent solutions, and that has a cost. hence our strategy is to target international brands as well as take on projects from smaller firms we think have a lot of growth potential. Also, fairs and exhibitions are getting more and more crowded and there always seem to be more of them. We want to invigorate our digital presence and generate a lot of online exposure, which is one of the reasons we are on Webpackaging. We think Webpackaging has a very professional image and what seems to be a higher quality of users and buyers compared to the general audience at a fair. This sort of premium user is willing to pay more to have better quality packaging and services to add more value to their products.

Do you have any news items you'd like to mention?

Well, our biggest news is the fact that our 3D prototyping service is online and proving quite popular. By using a simple printed item, we can provide 3D drawings and printed mock-up samples in a very short time. That means that we eliminate the need to wait for weeks or even months for a tangible item and also eliminates the need to set up commitments to pilot projects. We'll be showcasing this service at this year's Cosmoprof event in Bologna, and perhaps some others.

.jpg)