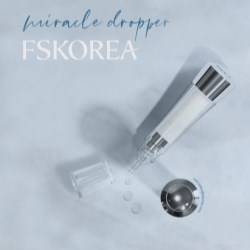

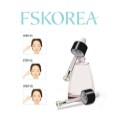

FS Korea has released a new take on one of its most popular items to date, its auto-fill droppers. The droppers, that simply require a quick twist to fill the dropper pipette with the liquid in the container, without pushing a button or depressing a bulb, are now being produced in a variety of new shapes and decoration options, as well as the ability to provide improved suction for viscous products.

Apart from more options for the containers, the droppers' dispensing system has also been improved in order to permit filling the bottles with just about any formula, including medium- or high-viscosity products, without a single air bubble being formed that could cause sputtering or inconsistent pumping.

The system is an extraordinarily clean one, with almost no residue left inside of the applicator, making it very easy to use. The button release mechanism requires minimal pressure to be activated. As the container is made of shatter-resistant PCTA, the product is guaranteed to arrive safely at its destination after shipping, and to last throughout its use in the home.

The new patent-pending droppers function with a high level of precision and efficiency to ensure the consumer always has the correct dosage in the pipette every single time it is used. All the consumer has to do is twist the dropper top while mounted on the container - the pipette automatically fills up thanks to the new design, primed for use. To release, the user simply has to press the button on top of the dropper to release the liquid onto the spot required.

Decoration options are myriad, supporting industry standards such as hot-stamping, silk-screening, product colouring and metallization. Though the innovation is a hot ticket item, the cost is nowhere near what one might expect, thanks to FS Korea's streamlined production processes and logistic know-how.

.jpg)

.jpg)

.jpg)

.jpg)