FS Korea, a company headquartered in Seoul that provides packaging solutions to the international cosmetic market, has released a new dropper system that's sure to turn heads. The new droppers pre-load when closed, ensuring there are no air pockets in the container that will filter up into the pipette, making dispensing more fluid and splatter free.

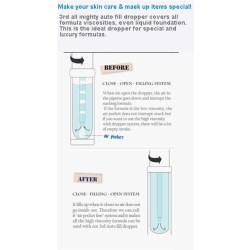

Previously, in order to fill most droppers, the user had to push out the air in the pipette by squeezing a rubber bulb. For liquid products, this wasn't a problem, as the air quickly bubbled up to the top of container and the pipette could be completely filled. With more viscous products, however, like liquid foundations, thick oils, or thin creams, squeezing the bulb would simply create an air bubble at the bottom of the container which would then be sucked back into the pipette upon releasing the squeezed bulb.

FS Korea's solution to this is a a simple and effective dropper system that uses the motions of twisting the dropper open and closed to maintain a perfect pre-load. Through a ratcheting action, closing the dropper fills it up when there are no air pockets in the container. So, when the consumer twists the dropper open, the pipette has already been filled and is ready for use. Dispensing the product empties the pipette which remains clear until put back in the container and twisted closed, filling it up.

The new droppers' exterior can be decorated in any number of industry-standard options, including hot-stamping, screen-printing and a variety of others unique to FS Korea, as one of the Asian region's foremost producers of luxury cosmetic packaging.

.jpg)

.jpg)

.jpg)

.jpg)