Public

LageenTubes Certificates

LageenTubes Image Gallery

LageenTubes Locations

LageenTubes News

LageenTubes Shows

LageenTubes Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Digital technology has gotten ever more complex, yet the value of this technology is difficult to define when you consider how much it can enhance market worth. The advancements in digital technology in the past few years have opened up many new possibilities, and LageenTubes recognized early on the value of exploring digital opportunties in order to revolutionalize the flexible tube industry.

As Managing Director at LageenTubes, David Deluya assures cosmetic brand owners that the direct to shape (DTS) digital printing offered exclusively by LageenTubes can allow their brand to become more impactful, differentiated and profitable.

LageenTubes' vision is to "provide worldwide customers with solutions which enable them to turn their brands into a winning reality". How do you do this?

One of the core pillars at LageenTubes is to continuously add value for its worldwide customers. The company specializes in the development, production and marketing of flexible tube packaging for both the cosmetic and pharmaceutical industries. LageenTubes' unique value proposition is based on the company always being at the forefront of tube decoration technologies such as the breaking DIGITAL printing technology.

LageenTubes identified the revolutionary cutting edge DTS digital technology, developed by VELOX, as the most suitable solution. This digital technology is revolutionizing the packaging industry by providing customers with outstanding solutions for better branding and enhancement of their shelf appeal.

Moreover, differentiation is a key success factor in the packaging industry where the brands are always looking for new and exciting ways to enhance sales, increase brand loyalty and consumer engagement as well as generate demand growth.

How is LageenTubes revolutionizing packaging decoration?

As an innovative organization, LageenTubes has always led the packaging industry as a pioneer in adopting the most advanced cross print technologies on extruded PE tubes.

Rather than adopting options already available in the market for digital printing, LageenTubes partnered with VELOX who have developed a new IP technology which delivers revolutionary capabilities for END TO END direct to shape digital printing.

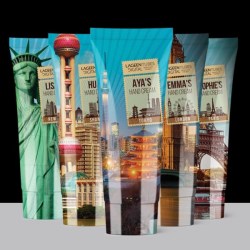

This digital printing enables total DESIGN FREEDOM as it offers complete end-to-end decoration, including printing on the cap, seamless 360° decoration without a gap or overlap, ultra-realistic images, and unlimited shades, gradients and half-tones. The cosmetic industry has been passionately waiting for these decoration features for a long time. Now, through means of a different specification, different configuration and different features, the dynamic needs of customers in the 21st century can be met head on.

How does direct to shape printing benefit brands?

For a number of years, brands have been calling out for unlimited design freedom but until now technology has limited this vision. Our technology is advancing the market as both design concepts and production lead times are optimized.

The offering from LageenTubes benefits both the supply chain and lead times, as well as enhancing the marketing opportunities for the brand. For example, operational agility and brand optimization are no longer restricted to choosing one option over the other. Beauty brands can now have both which is beneficial for both marketing and procurement.

The operational agility revolutionalized by our digital printing includes shorter lead time, immediate proofing and no replacement cost, and ongoing brand optimization benefits A/B testing, limited editions, personalization and segmentation.

What are the marketing and design benefits?

Our new printing technology allows for 360° design which is a revolution for both marketers and designers. Throughout the years, technology has constrained the packaging decoration industry due to inabilities such as overlapping of plates or the need of matching the front with the back. This is now a thing of the past.

New opportunities for brand optimization are currently available as we now can support brands from the earliest concept stages. Practically, we can create an actual printed designed tube by simply sending a computer file to the digital printing machine, resulting in a physical, full size and fully printed tube for immediate proofing.

The speed of this process allows marketing teams to fully control A-B testing or conduct focus groups using real tubes with different designs and base decisions upon pre-launch consumer experience. Additionally, this new technology allows us to present multiple designs so that marketing teams can explore different ideas for segmented markets and unique target audiences to see what works the best.

Does this benefit procurement too?

Yes, the advantages of the new digital technology benefit both marketing and procurement. Cosmetic companies that can offer shorter lead times, and have more flexibility and availability, can respond quickly and more efficiently to dynamic changes in the market. The freedom to make decisions upon real time sales performance in every segment and geographical area, gives our customers an operational agility throughout the supply chain that has never before been seen: shorter lead time, shorter proofing and shorter changeover, at any time. We can produce any quantity, and all in conjunction with advanced design benefits.

This supply chain optimization was limited previously. Now, we are revolutionizing it.

Are there any design limitations?

When using analogue process technology, there have been limitations due to the colors and plates. Color ranges could be extended with CMYK printing, and although there are many benefits to the technology, there is always an overlap with plates, or the need for a separate front and back design.

Our direct to shape digital print technology of 360° continuous design offers true design freedom. Myriad colors are available, ultra realistic images can be recreated and unlimited gradients reproduced with fantastic effect.

In addition to continuous design, our new technology allows the cap to be incorporated into the decoration instead of keeping it as a separate feature. End-to-end printing is a particular strength of the new Velox digital technology and a true revolution for the packaging industry. Our combined expertise offers a premium differentiator to enhance brand value.

On top of that, the printing process allows for a matt or gloss finish and UV effects to be done at the same time instead of as separate processes which is a significant production time saving.

The digital printing can also be done on sustainable eco-friendly PE tubes. This is a unique revolution that is presented by LageenTubes. For the first time in the world of cosmetics packaging, LageenTubes is introducing its revolutionary direct digital printing onto 'green plastic' tubes for the SUSTAINABLE DIGITIZED TUBE.

The ability to bring together 2 major pillars of consumer experience through the packaging, creates differentiation and unique impact for the cosmetic brands — the combination of sustainability with outstanding decoration. A sustainable, eco-friendly packaging printed with digital design without limitation gives our customers a competitive advantage that is appreciated by consumers.

LageenTubes is going DIGITAL and invites its partners to use the 3D Pick-a-Pack platform to see how their brand can benefit from this technology.

Find out more about Velox.

Pictured: David Deluya, Managing Director at LageenTubes, end-to-end 360° continuous design printed tubes, sustainable digitized tube.