Public

Lameplast 3D Catalog

Lameplast Catalog

Lameplast Documents

Lameplast Gallery

Lameplast Locations

Lameplast News

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

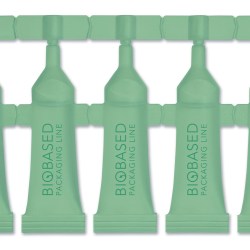

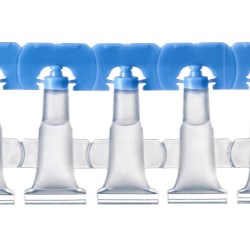

The future of packaging? It's green! And so is the future of marketing. After launching the first injection molded single-dose in Green Polyethylene (Bio PE), Lameplast Group is now able to offer a full range of bioplastic containers made from raw vegetal materials as an alternative to those made from oil-based plastic. Bioplastic is a 100% renewable source unlike oil-based plastic.

Are you green?

Using these new plastics, Lameplast Group is implementing many years of studies aimed at developing "BIO" materials. Based on initial positive feedback, the bio-polymers can now be used to make single-dose and multidose containers for foodstuffs, cosmetics and personal care products.

Why use bio-based plastics?

Unlike traditional plastics, Green Polyethylene is not made from oil but from ethanol obtained from sugar cane. The result is a unique product with the same technical characteristics, appearance and versatility as traditional fossil-based polyethylene, as well as many other benefits:

- Sustainable Sugar cane crops used by Braskem for the production of Green Polyethylene fulfil highest sustainability standards defined in Braskem Code of Conduct.

- Renewable Green Polyethylene is made from ethanol obtained from GMO-free sugar cane grown in Brazil - a renewable raw material.

- It helps to reduce greenhouse gas emissions Sugar cane captures and holds CO2 from the atmosphere during every growth cycle, contributing to reducing greenhouse gas emissions

- 100% recyclable At the end of its lifespan Green Polyethylene can be recycled in the same chains already developed for conventional PE.

The Bioplastic used by Lameplast Group is "I'M GREEN™ POLYETHYLENE" by Braskem distributed by FKuR Kunststoff GmbH.