Public

Mecmesin Catalog

Mecmesin Certificates

Mecmesin Documents

Mecmesin Locations

Mecmesin News

Mecmesin Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

The customer had a number of Tornado closure torque testers, and wished to carry out regular validation checks without the need to return the units to either Mecmesin or an approved laboratory.

Solution

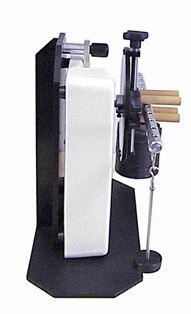

The closure tester was securely mounted in the vertical plane and a load beam was placed centrally in the universal-clamping fixture. The loadbeam had 5 hooks equi-spaced either side of the axis of the transducer.

The loadbeam located off the central leadscrew of the clamping fixture ensured centralisation. Calibrated masses were then hung at different positions along the loadbeam and once stabilised the displayed torque reading noted.

This method provided a 5-point check calibration, in both clockwise and counter-clockwise directions, all possible without having to reposition the unit.

System

Closure tester support band

- Load beam

- 2 weight hangers

- 5 5N calibrated masses

.jpg)