If this is your company, CONTACT US to activate Packbase™ software to build your portal.

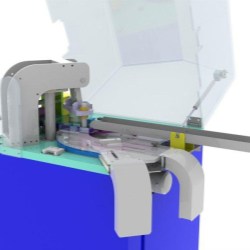

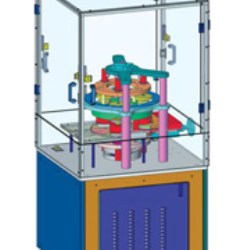

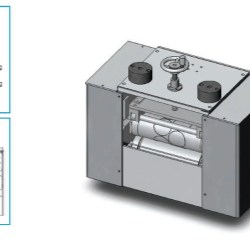

MMC's Multi-Purpose Frame can be customized to perform various functions for the after-molding process of caps and closures. This compact design may also combine two post-molding operations within this small footprint.

With a system capacity of 1-across and up to 53mm nominal diameter this machine can run up to 85ppm. Furthermore, it is highly cost-effective, leading to high standards for quality, technology, reliability, and robustness.

Key benefits inlude:

- Cost-effective equipment that respects MMC

- standards for quality, reliability and robustness

- Small footprint for optimum space utilization

- Fast delivery

- Easy tooling changeover (under 30 minutes)

- Unparalleled customer service

- Onboard vision inspection system (optional)

The MPF can be adapted for several types of post-molding operations:

- Punch and Die lining

- Rotary die lining

- Pre-cut liner disk

- Multiple-piece custom assembly

- Cut to post tamper evident band slitting and/or band folding

- Closing caps with various hinge styles and latching features

In a market that is constantly searching for innovative caps, MMC Packaging has the automation solutions you are looking for. The experienced engineering team designs reliable and durable machines that can withstand the harshest conditions. Throughout the life cycle of the equipment, MMC Customer Service is always on hand to assist and offer services that will continuously enhance the efficiency of the equipment.