If this is your company, CONTACT US to activate Packbase™ software to build your portal.

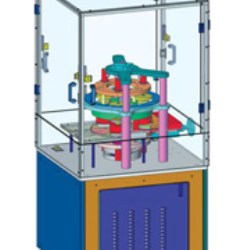

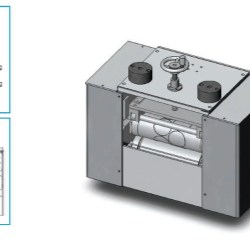

Major upgrades have recently been recently performed on the LM-270LX, one of MMC's best-selling cap lining machines, making it more robust and able to reach an even higher throughput rate than it already offered.

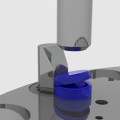

The basic principle stays unchanged: as with all of MMC's standard cap lining machines, the new LM-270LX utilizes a multi-station rotary indexer to receive caps into a pocket wheel in multiple lanes. While the adaptor ring of the LM-270LX is backward compatible with the previous LM-270L toolings, the new indexer is more robust and can now reach 200 cycles per minute.

Several other features were enhanced with the following key highlights:

- The main RAM assembly has been redesigned to make the connecting rod between the lower punch plate and the crankshaft more robust;

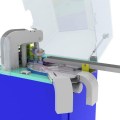

- The paper feed assembly has been redesigned to achieve better control over the co-action of the lower and upper rolls, making the tracking of the lining material more precise;

- A new thru-beam sensor has been integrated to the system to allow for better web motion detection;

- The new drive support assembly allows for better access and maintenance.

With these improvements, the LM-270LX is a high-speed entry-level precision lining machine capable of processing two and now three caps at a time, with a throughput of up to 600 caps per minute depending on the operating mode and the diameter of the caps.

Click here to see a video of MMC's LM-270LX cap lining machine in action!