If this is your company, CONTACT US to activate Packbase™ software to build your portal.

"I need plastic pallets for my activity." This starts being the approach in many companies, continuing with: Where to buy them? What type of plastic pallet to choose? What should I look for? And ultimately, where should I start?

Frequently, managers and directors of logistics, export, procurement, production, etc. departments or sectors such as commercial distribution, food, beverages and automotive, among others, are faced with this problem.

At Nortpalet we propose a series of questions that the company and the person responsible for buying a plastic pallet should take into account and respond before making a decision. When selecting a plastic pallet, it is important to define the following parameters:

What measures are needed

Within the most standard measures of the market we can find 4 sizes:

- Quarter pallet (600x400mm) is a plastic pallet widely used as a product display in the large distribution and whose trend of use is increasing.

- Half pallet (600x800mm) fundamentally used to increase the turnover of products in the stores, to improve the efficiency of the replenishments and to increase the number of references per shelf.

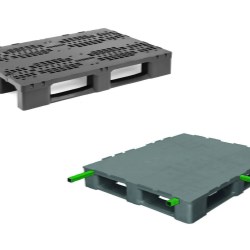

- Euro pallet (1200x800mm) is the most generic standard model used in most logistics circuits in Europe.

- American pallet (1200x1000mm) is also a standard plastic pallet intended for more industrial use due to its larger dimensions and greater load capacity.

Also, there are specific non-standard uses where different particular dimensions are required.

Which model is the most appropriate

Once the size of the pallet is defined, it is necessary to discriminate by the use that will be given to the pallet to determine the most suitable product range:

- One-way light pallets (up to 9 kgs approx) are the most economical pallet range, as their name indicates are very light, and their main use is for export of all types of products .

- Heavy duty (17-25 kg approx) pallets are those models that due to the high load capacity, high strength and great durability generate a logistical cost for the use of a very high efficiency.

- Intermediate pallets (10-16 kgs) are those that meet some characteristics of the previous two, are models intended for reuse but with the lowest possible weight that allows obtaining an intermediate solution in the price.

What will their manipulation be?

Logistics in closed circuit, open circuit or export, type of storage, type of goods to be transported, automatic palletizing, rollers conveyors, etc. These concepts will define some characteristics that should have the pallet selected, ie with runners or without, reinforced or not reinforced, nestable, etc.

What temperatures will the pallet need to withstand?

Especially in the food sector where pallets enter refrigeration chambers or industrial freezers. Not all materials behave in the same way in the cold and this is therefore essential for their choice.

What loads will the pallet need to endure?

Both dynamic load (handling with a fork lift or pallet truck), static load (with the pallet on the ground without handling the load), as rack load (when the pallet is going to be on a storage shelf on only two supports). It is important to note in this case the weight of the pallet. That the plastic pallet weighs more will mean that it contains more raw material and that therefore offers greater resistance, which in part guarantees a better result, and for sure a greater durability.

At Nortpalet we have thought about our customers and their needs. And once again in our commitment to the environment, the "Buy-back Program" has been developed, which allows reducing the environmental impact with the repurchase of used pallets at the end of their useful life. Thanks to the recycling processes it is possible to recover the materials to be incorporated in a new product and suitable for use, avoiding the saturation of landfills and the generation of waste. Therefore, the customer of Nortpalet is acquiring an asset, recovering the residual value of the same at the end of its cycle of use.