If this is your company, CONTACT US to activate Packbase™ software to build your portal.

The meat industry is one of the sectors where the plastic pallet is most established, mainly due to the hygiene conditions demanded by the different applicable legislations, among them the HACCP directive. In environments where cleaning and hygiene are very strict, the plastic pallet plays a transcendental role because it can be easily washed after each use and cannot be penetrated by liquids or other elements of the production process.

As the meat sector has grown, consolidating and adapting its processes to meet the demands of an increasingly demanding consumer and a highly regulated market, very demanding quality standards have been developed that ensure the best conditions for its processes. In most cases, the handling of meat and poultry is done by plastic boxes of standardized dimensions and whose raw material has a certification for food use. These boxes are secondary packages that are in direct contact with the food, and whenever they are used, these are properly cleaned for their next reuse.

The boxes with their contents are manipulated, stored and transported on top of pallets. These pallets coexist and transit with the boxes in the same rooms where the product is handled, so if you want to ensure a hygienic environment, it is important that the pallets meet certain hygiene conditions.

"Plastic pallets are impermeable, so they cannot nest bacteria and / or parasites that can accidentally contaminate processed food."

Plastic pallets are impermeable, so they cannot nest bacteria and / or parasites that can accidentally contaminate processed food. In addition, unlike other pallets such as wood pallets, they can be washed after use, which guarantees that the equipment arrives with the best hygiene conditions to the processing plants avoiding introducing any type of contamination of the exterior or bad smells in the process rooms.

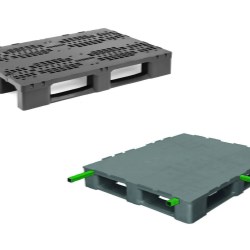

Two main types of pallets in the meat industry

Those that are captively used in processing plants and therefore never go abroad, so many companies in the sector choose the CLEAN range of Nortpalet, whose performance, functionality and durability are well contrasted. It is also common to find producers using the CLEAN range to deliver final product to their nearest customers in cases where there is a closed circuit that allows the return of the equipment to origin.

However, many producers use the Nortpalet BASIC range pallets for the delivery of finished product to the distributor or retailer because of the difficulty of many companies in the sector to recover the pallets after delivery to the customer so the cost of the equipment has to be reduced.