If this is your company, CONTACT US to activate Packbase™ software to build your portal.

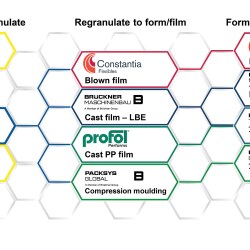

PackSys Global is currently active in two initiatives to promote the circular economy. As an international consortium, the Tube Circle brings together stakeholders from the entire value chain to close the cycle for tube packaging as far as possible. Our initial goal is to drive material reduction.

Secondly, we aim for optimised recyclability and thus mono-material tubes. Currently, many tubes are made of polyethylene and the caps are made of polypropylene. What would be the advantages of a purely PE and/or PP tube? And thirdly, we want to examine the use of bio-based materials with the goal of further

increasing tube sustainability.

The initiative Plastic Squeeze Tubes, co-founded by us, arose from the CEFLEX project (for flexible plastic packaging). It focuses on developing design guidelines for the recyclability of tubes in Europe and their compatibility in the recycling stream. This is a major challenge: recycling streams in Europe are still very diverse and urgently need to be harmonized and consolidated. Since tubes, like many other types of packaging, do not have their own sorting streams, this is also about the role played by tube quotas in the recycling stream.

With our new technology for 360° printed laminate tubes, we have already taken a convincing step in the direction of sustainable tubes. Thanks to direct print, NEOSeamTM tubes neither need additional material for labelling nor for creating the side weld seam, making them ideally suited for mono-material solutions.

"We want to strengthen even further the importance of tubes compared to other packaging. It's not only about the question of recyclability - the increased use of recyclates is also important." — Dr. Peter Schkoda, Head of Global Sales Tubes PackSys Global

The question of which material is best generally plays a major role for us. Among other things, we carry out tests with recyclates produced by EREMA. The barrier layers are also important. The body of a tube currently consists of several PE layers in which an aluminium barrier layer (aluminium barrier laminate, or ABL for short) is embedded. Tube manufacturers and brand owners are currently replacing ABL tubes with PBL tubes (plastic barrier laminate, i.e. tubes with a plastic barrier layer) for better recyclability. Our machines can already produce tubes with different barrier layers. If the EVOH barrier layer (ethylene vinyl alcohol copolymer) used makes up less than five percent of the total weight of the body, the tube is recyclable as a mono-material.

What is certain is that the linear economy that has been practised across the board for a long time now is no longer sustainable. A general rethink has to take place in all areas. In the long term, this can only work if we consider all the effects of our actions, if we regard every raw material as valuable, and if we strive to leave behind an ecological footprint that is positive, rather than just as small as possible.

The first steps have been taken and developments are progressing quickly - a lot has happened since our first booklet. What was progress yesterday has become obsolete today. What is only an idea today could be a reality tomorrow. But we must continue to act. There is still a long way to go. And, most importantly, everyone involved must pursue this goal together. That includes not only producers, manufacturers and recyclers, it also includes consumers.

To find out more about the circular economy in the plastics industry, read the full report published by PackSys Global parent company, Brückner Group.

PackSys Global offers complete systems for extruded tubes and laminate tubes. Contact us to find out which of our packaging machines are best suited to your company and industry.

.jpg)

.jpg)

.jpg)

.jpg)