If this is your company, CONTACT US to activate Packbase™ software to build your portal.

.jpg)

New addition to the portfolio

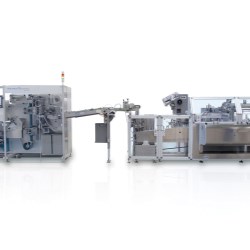

Tube filling solutions for effervescent tablets

Following the acquisition of Medipac AB in November 2015, Romaco is now in a position to offer tube filling systems for effervescent tablets for the first time. The core competency: gentle filling of fragile effervescent tablets according to the rotation principle.

The Romaco Group’s decision to purchase the assets of Medipac AB, the Swedish manufacturer of tube filling machines, rounds off its portfolio in the effervescents sector. These systems for the primary packaging of effervescent tablets will in future be sold worldwide under the umbrella brand Romaco Siebler. Three different tube filling systems in different performance classes are currently available in the Siebler MF series. With a maximum output of 120 tubes per minute, the Siebler MF 120 is designed for very high production speeds. The mid-range MF 70 is currently the top-selling model. The semi-automatic Siebler MF 20 achieves up to 20 tubes per minute. All series apply the rotation principle to fill tubes with effervescent tablets.

Filling according to the rotation principle

The effervescent tablets are first guided through up to eight channels, where they are counted still lying flat down and thus fed to the filling station. They then pass through filling tubes which rotate at high speed. The resulting forces cause the tablets to stand up automatically and slide upright into the waiting tubes, which are also rotating fast. The suction effect of this rotation creates air cushions, which centre the tablets and prevent them from hitting the tube walls. The fragile effervescent tablets are thus processed extremely gently. Both the tablet erection speed and the filling speed can moreover be adjusted by altering the number of rotations per second. The products can be packed in either plastic or aluminium tubes. A wide range of products in different sizes and shapes can be handled.

Fewer parts, modular concept

Only a small number of format parts – which are easy to install and clean – are required to equip the basic machines. There is no need to change the format parts in order to fill tablets into different tube lengths; only a few minor adjustments have to be carried out. The same applies to the filling volume, which varies from 5 to 30 tablets and can easily be adapted according to the tube size. Downtime and retooling times due to product changes are therefore reduced to a minimum. All machines in the Romaco Siebler MF series have a modular architecture and can be upgraded with numerous options if desired. Various integration friendly extras are available for feeding the tablets, tubes and caps. The level of automation for controlling the system is also individually configurable. Diverse instruments can be implemented for monitoring the process. Inkjet coding and integral print inspection are offered as marking options.

Line integration

With its Innojet, Kilian, Siebler and Promatic product lines, Romaco is a leading manufacturer of all-in-one solutions for the effervescent sector – spanning coatings for taste masking and granulation, tableting, packing in tubes or strips and a wide range of cartoning systems. The Romaco portfolio includes various flexibly configurable transfer units for connecting the tube filling systems directly to process and secondary packaging machines installed upstream or downstream. When it comes to expert processing of air, light and moisture sensitive effervescent products, Romaco Siebler can draw on a long tradition.

The Romaco Group

Romaco is a leading global supplier of Processing and Packaging equipment, predominantly for the pharmaceutical industry. Divided into three business areas, Processing, Tableting and Packaging, the company develops engineered system solutions for the pharmaceutical market, but also supplies the cosmetics, food and chemical markets. Romaco operates from four European locations with the headquarters in Karlsruhe, Germany. The company serves the multiple industries through a total of eight brands: The packaging product lines Noack, Siebler, Bosspak, Macofar, Promatic and Unipac are manufactured in Karlsruhe, Germany and in Bologna, Italy. The tableting product line Kilian is produced in German Cologne while the Innojet product line in German Steinen is responsible for granulation and coating. Romaco’s product portfolio includes primary, secondary and final packaging, aseptic and non-aseptic liquid and powder filling, tablet press technologies, granulation and coating. Over 12,000 Romaco installations are currently in operation in more than 180 countries. The company’s worldwide customer base is supplied and supported by over 500 highly skilled and committed employees.

In 2014 the Romaco Group was voted by “Wirtschaftswoche”, the prestigious German business weekly as one of Germany’s best 50 innovators among small and medium-sized enterprises. In this corporate benchmarking contest, Romaco was named runner-up in the “Process and Packaging Machinery” category. In the “Pharmaceutical Machinery” segment, the Group was awarded first prize.