We help skincare, personal care, beauty, and cosmetic companies to build measurable success with advanced technology and high efficiency.

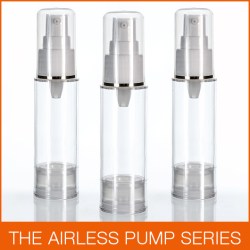

The bottles are equipped with two plastic layers: a tough and resistant exterior made of PETG and a highly compatible inner layer made of EVOH+PP. As the product is dispensed and pressure sets in, this inner container contracts and separates evenly from the exterior bottle wall. The use of EVOH and PP also ensures that the container will offer proper protection against chemical and microbial contamination as well as remain neutral while holding stronger formulation.

Eco-Airless bottles use the minimum amount of plastic required and offer a truly eco-sensitive airless package. It is an updated and greener option that replaces bulky, multi-component airless packaging. It also eliminates the costly production process needed to create syringe airless bottles, which use numerous components and cost anywhere from 30% to 50% more than the Eco-Airless.

All Eco Airless Bottles can be produced with PCR PE, and immediately added to a current product line. It is a swift and cost-effective transformation to help brands stand in line with sustainable schemes.

.jpg)

.png)