If this is your company, CONTACT US to activate Packbase™ software to build your portal.

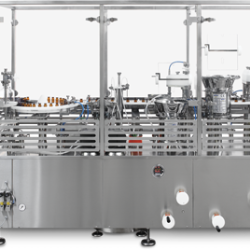

The modern design of STERILINE filling machines takes into consideration the newest requirements of the filling process. According to the GMP conform modular design of STERILINE filling machines, filling and closing stations can be arranged in one single machine platform. This advanced design enables STERILINE to customize the process by combining in one common base machine.