If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Tekni-Plex will be showing its line of medical device films, high-performance coated Tyvek® and coated paper rollstock and lidding material, as well as adhesive and extrusion laminations, at HealthPack, March 10-12, Sheraton Charlotte Hotel, Charlotte, North Carolina, Booth 6.

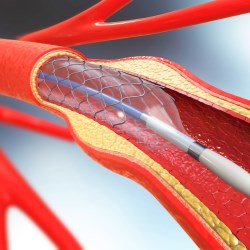

For thermoformable rigid medical device tray applications, Tekni-Plex will be featuring its TekniMD® PXA structure which is a lamination of its proprietary PX film and Aclar®. It is ideal for products requiring an enhanced moisture barrier.

Also suitable for thermoformable medical device applications is TekniMD® COC.PG, a PETG/COC/PETG coextrusion. Both TekniMD® films structures can be sterilized using gamma, EtO or e-beam and are available in clear, white or blue tint.

Tekni-Plex’s coating expertise also delivers materials with optimal breathability for fast EtO sterilization cycles, versatility (seals to a wide variety of flexible and rigid films), clean peel and robust barrier.

Additionally, coated Tyvek® options offer exceptional tear strength and puncture resistance. Up to eight times stronger than medical-grade papers, the material is ideal for demanding Class II and Class III medical device applications.

High-performance coated paper structures offer a cost-effective option, making them ideal for high-volume applications. The company also manufactures custom extrusion or adhesive laminations to suit a specific packaging application. Both coated Tyvek and coated paper structures can be sealed to Tekni-Plex’s PX films providing a total package solution.