In today's fast-paced world, ensuring the safety of food products is a top priority for businesses and consumers alike. One crucial aspect of food safety is the use of food-grade plastic. In this blog post, we will delve into what food-grade plastic is and how it plays a vital role in preserving the quality and integrity of food products.

HOW DOES FOOD GRADE PLASTIC BECOME CERTIFIED?

Food grade plastic is not just any ordinary plastic; it undergoes a rigorous certification process to ensure its suitability for food packaging. Various regulatory bodies, including the Food and Drug Administration (FDA), have established guidelines and standards for food grade plastic. These standards assess factors such as the plastic's resistance to leaching chemicals, its compatibility with food, and its ability to maintain the freshness and safety of food products.

PLASTIC RESINS APPROVED BY THE FDA AS FOOD SAFE

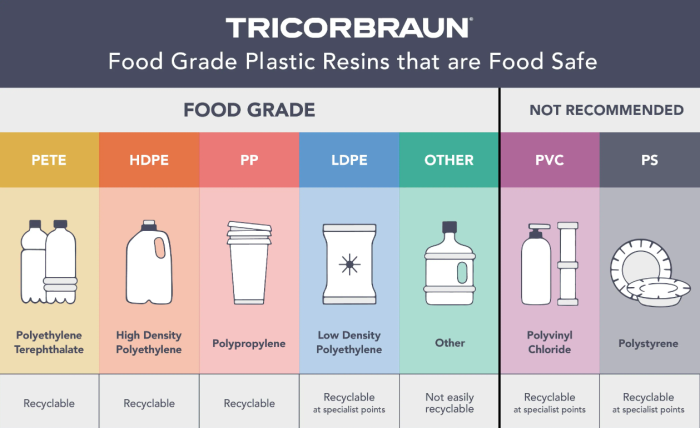

The FDA has approved specific types of plastic resins for use in food packaging. These resins are known for their safety and ability to withstand the demands of food storage and transportation. Some of the FDA-approved plastic resins (which are also BPA free) commonly used in food-safe plastic containers include:

- Polypropylene (PP): PP is widely used in food packaging due to its excellent chemical resistance and durability. It is commonly found in microwave-safe containers, food storage containers, and bottle caps.

- High-Density Polyethylene (HDPE): HDPE is known for its strong barrier properties, making it an ideal choice for food and beverage containers. It is commonly used for milk jugs, water bottles, and juice containers.

- Polyethylene Terephthalate (PET): PET is a lightweight and transparent plastic that is widely used for bottling beverages, such as water, soda, and juices. It is also commonly used for food trays and salad containers.

COMMON PRODUCT USES FOR DIFFERENT RESINS

Each type of FDA-approved plastic resin has its specific applications in food packaging. Here are some common product uses for different types of food-safe plastics:

- Polypropylene (PP): PP containers are commonly used for packaging deli meats, dairy products, and condiments. They are also suitable for microwave-safe food storage containers.

- High-Density Polyethylene (HDPE): HDPE food-safe containers are widely used for packaging milk, water, and other beverages. They are also commonly used for food storage containers and lids.

- Polyethylene Terephthalate (PET): PET is commonly used for bottling carbonated beverages, juices, and water. It is also suitable for packaging salad dressings, condiments, and fruit containers.

Food-grade plastic plays a vital role in ensuring the safety and quality of food products. By adhering to FDA guidelines and using FDA-approved plastic resins, your business can confidently package its food products in containers that maintain the integrity and freshness of the contents. At TricorBraun, we offer a wide range of stock and custom packaging options to meet the unique needs of your business.

Remember, when it comes to food safety, it is crucial to choose food-grade plastic containers that are specifically designed to protect your products, including solutions that are impact resistant, have high melting points, and are intended to handle long-term contact with food. Talk to our packaging consultants today to explore the best packaging solutions for your business's needs.

TALK TO A PACKAGING CONSULTANT

Whether you’re looking for a stock package or a groundbreaking custom design, TricorBraun’s proven process will guide your packaging decisions from napkin sketch all the way to the retail shelf.