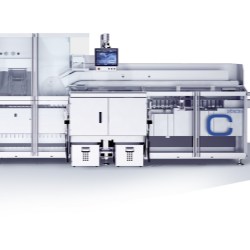

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Ideal for complex product shapes

Maximum machine efficiency characterizes the linear feeder even in demanding cases. It handles different products of complex shapes, ones with noticeable differences in tolerance range, unconventional circular or star-shaped blister configurations, and products susceptible to shingling.

Highlights

- Very fast, tool-free changeover involving just two format parts

- Ideal for complex shapes and in case of widely varying thickness tolerances

- Flexible application due to integrated control cabinet

- Suitable for upgrades

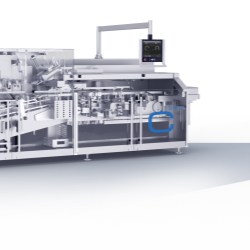

Operating method

- The products pass from the hopper to the vibratory chute. Dedusting here removes dust and product chips

- The products continue through the product chute into the supply chamber

- Vibratory movement shakes the products into a single layer on a sorting plate; surplus products are swept away

- A vacuum plate with suction cups picks up the products from the cavities of the sorting plate and places them into the formed pockets

- A suction cup is available for each individual product