If this is your company, CONTACT US to activate Packbase™ software to build your portal.

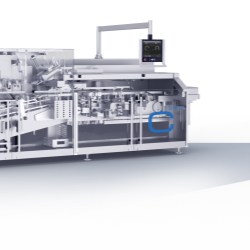

Proficient system for products of simple shape

The vibratory feeder guarantees efficient feeding with a high fill quota and is ideal for all products of simple shape – such as tablets, spheres, caplets or capsules. Operating personnel have a clear view of the whole feeding process.

Highlights

- High-speed feeder for standard product shapes

- Few, quick-fitting and easy-to-clean format parts

- Straightforward, tool-free format changeover

- Available in two versions for continuous motion blister machines: with fixed chute for PVC forming materials or with a filling roller for aluminum forming material.

Operating method

- The products pass from the hopper to the vibratory chute. Dedusting here removes dust and product chips

- The products slide into the vibratory bowl of the round vibrator via the product chute

- The option with a fixed chute is used with continuous motion blister machines and PVC forming material. The products pass through the feed track and are directly placed into the formed pockets.

- The option with a filling roller is the right solution for continuous motion blister machines and aluminium forming material. The products move from the feed track into the holes of the filling roller and are then directly placed into the formed pockets.